How Salesforce Implementation Transforms the Manufacturing Industry?

The manufacturing sector is going through a digital transformation age and to remain competitive, companies have to be agile, efficient, and real-time. The conventional processes are no longer sufficient to achieve the rising pressure in the need to be more productive and deliver better customer service. Enter Salesforce, the potent cloud-based customer relationship management system that is changing the manufacturing processes globally. This blog will discuss about How Salesforce Implementation Transforms the Manufacturing Industry and how they implementation of Salesforce are assisting manufacturers to streamline their operations, achieve higher productivity, and customer satisfaction which results in sustainable growth.

1. The Manufacturing Industry’s Key Challenges

To discuss the ways Salesforce is changing the industry, it is necessary to first grasp the critical issues that manufacturers are facing at the moment:

A. Fragmented Systems

- In many manufacturers, the isolated legacy systems are still used in different departments including inventory management, production planning, and customer data. These disjointed systems cause inefficiencies and hindrance of cooperation, and it is hard to have such a unitary perspective of the business.

B. Inefficient Operations

- Delays and errors occur because of old systems and manual processes. Manufacturers face difficulties in coping with the growing needs of consumers to have rapid and quality production because of cumbersome workflow resulting in low efficiency and high operation costs.

C. Demand Volatility

- This is a challenge that has always existed in an ever-changing marketplace where the ability to predict the demand of the customers is a challenge. The absence of real-time data can cause manufacturers to over-produce or stock out, which can hurt revenue and customer satisfaction in a negative way.

D. Growing Customer Expectations

- With the changing needs of the customers, manufacturers need to be prompted to deliver the appropriate products at the appropriate time and quality. The rate of evolution in the preferences of customers compels manufacturers to implement flexible solutions based on real time which assists them to remain ahead of the market.

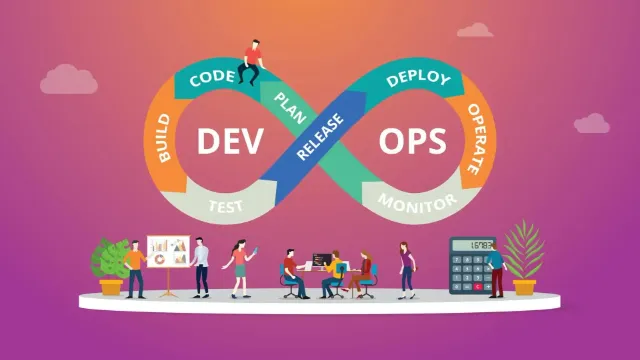

2. The Power of Salesforce in Manufacturing

Salesforce is a set of solutions that integrates all the dynamics of the operation of a manufacturer in a single platform. Manufacturers can use Salesforce Manufacturing Cloud, Field Service, Order Management and Einstein AI to see, automate, and make data-driven decisions.

A. Centralized Data for Smarter Decisions

- Salesforce brings all data together like all customer data, inventory and production schedules into a single platform. That type of data integration will eliminate silos, increase access to real-time data, and allow manufacturing teams to make better decisions.

B. Automation to Optimize operations

- Salesforce automates sales-based activities such as processing orders, creating invoices and monitoring inventory. This is not only time and labor saving but also eliminates any errors and speeds up the work process hence ultimately, faster production turnover and money saving.

C. Real-time Insights and Analytics

- Salesforce gives manufacturers real-time information about all data such as inventory numbers, production capacity etc. The Salesforce Einstein provides AI-based predictive analytics that can assist manufacturers to precisely predict demand, modify production timetables, and make efficient use of resources.

Also Read: Good Data Practices on Salesforce with Backup and Recovery Tools

3. How Salesforce Transforms Manufacturing Operations

The Salesforce manufacturing cloud is specific to the needs of the manufacturers. Key features include:

A. Salesforce Manufacturing Cloud

- Account-Based Forecasting: It is the combination of customer information and operational data to develop accurate demand forecasts. This will minimize surplus production and prevent stockouts so that inventory levels will match demand.

- Sales Agreement Management: Compiles and automates monitoring of the pricing, terms and volume promises and assists the manufacturer to be compliant and transparent in the supply chain.

- Teamwork Tools: The system incorporates the elements of cross-functional teams working together on production plans, inventory changes, and sales predictions to improve communication between departments.

B. Field Service Management

Field Service solution of Salesforce can help manufacturers streamline field operations by:

- Maximizing Scheduling and Routing: AI-based scheduling of the salesforce ensures the technicians are given the right job in terms of location, skills, and availability, thereby reducing time wastage on travelling as well as increasing efficiency of the services offered.

- Real-time Tracking: It gives technicians and dispatchers real-time information which enables them to process service requests, track the status of the job, and enhance communication with the customer.

- Predictive Maintenance: The internet connects the equipment and the IoT, and most of the time, it helps manufacturers decide the equipment call for maintenance before failure, thus reducing unplanned downtimes and extending their life.

C. Order Management Automation

Salesforce Order Management offers a full package of order management: processing the order to fulfilling it:

- Unified Order View: Coordination of all sales channels: The integration of all sales channels gives a 360-degree view of the orders and inventory of a customer, enhancing the accuracy of the order and minimizing errors.

- Automated Processes: Major activities such as order entry, invoicing and tracking the shipments are automated thereby saving on manpower and accelerating the order processing.

- Improved Customer Communication: Customers are constantly notified of the order status, and this will result in customer satisfaction, because of automated order status.

Also Read: How to build scalable applications in Salesforce?

4. Real-World Impact: How Salesforce Improved Manufacturing Operations

To gain insight into the concrete gains of Salesforce, we should take a practical situation of a manufacturing firm that had a problem with long lead times, slow delivery times, and a lack of visibility into operations. The adoption of Salesforce helped the company to do the following:

A. Unified Data Access

- Salesforce combined all types of systems sales, inventory, and production with real-time results. Having this integrated data, the company would see where things were going, where the bottlenecks were, and make decisions based on data that enhanced efficiency of their operations.

B. Automated Processes

- Some of the most important processes that were automated by the manufacturer were order processing and inventory management. Automation minimized the chance of human error, hastened workflows and allowed resources to be channeled to more strategic activities.

C. Better Forecasting

- The company enhanced its level of demand forecasting by utilizing Salesforce Einstein AI. The manufacturer would be able to produce with improved visibility of customer needs and production capacity and therefore there would be no overproduction and underproduction.

D. Reduced Lead Times

- The company was able to schedule production in real-time and streamline optimization to minimize lead time and provide quicker deliveries and customer satisfaction.

5. Best Practices for Successful Salesforce Implementation in Manufacturing

These are the best practices that manufacturers should embrace to take the full advantages of Salesforce implementation:

A. Perform an Extensive needs assessment

- The thing is that you need to analyze the specific needs of your organization before adopting Salesforce. Establish areas of focus, such as inventory, demand forecasting or order processing, etc., and focus on those areas. This will assist you in configuring the Salesforce solution that best fits your business needs.

B. Secure Inter-Departmental Cooperation

- Salesforce is an inter-departmental tool, and its efficiency is determined by the interaction of various departments. Promote interdepartmental collaboration between sales, production and service teams in specifying workflow and facilitating integration of data among systems.

C. Invest in Training

- Invest in thorough training to make sure that your team can enrich the capabilities of Salesforce to the full extent. Ensure that all the stakeholders learn how to make the best use of the platform, including data entry to real-time report generation.

D. Monitor and Adjust

- After implementing Salesforce, keep on checking its performance and provide corrections as necessary. Optimize the processes and modify the working workflows with real-time analytics and employee feedback to ensure that the system is operating as it was supposed to be.

Also Read: What challenges can Salesforce Managed Services help businesses overcome?

6. Conclusion: The Future of Manufacturing with Salesforce

Salesforce is changing the manufacturing sector by offering a set of solutions that helps manufacturers with optimization of operations, enhancing collaboration, and competing with the demands of the changing customer. With the help of such tools as Salesforce Manufacturing Cloud, Field Service, and Order Management, manufacturers will be able to optimize their processes, cut expenses and innovate.

Salesforce will be a critical solution for manufacturers who want to remain competitive in a highly dynamic business world. It could be the automation of work processes, the accuracy of the forecasts, or the ability to communicate with customers better, Salesforce is what will help unlock a new dimension of efficiency and customer satisfaction in the field of manufacturing.

The manufacturing industry is no longer able to work in silos in the digital world. Salesforce offers a unified system that will be required to modernize the operations, raise agility, and guarantee sustainable growth. Through the adoption of Salesforce, manufacturers have an opportunity to future proof their business and keep succeeding in a highly competitive global economy.

FAQs: Frequently Asked Questions

1. What is Salesforce Manufacturing Cloud?

- Salesforce manufacturing cloud is a collection of products that are tailor-made to meet the special demands of manufacturers. It assists in consolidating production, sales and inventory information under a single platform where processes become easier to manage and streamline, demand prediction, and cross team collaboration is facilitated.

2. What is the benefit of Salesforce in manufacturing demand forecasting?

- Salesforce can utilize AI-based applications such as Salesforce Einstein to process previous data, real-time trends, and customer activities to enable manufacturers to better forecast demand. This will enable more intelligent decision-making during production planning and less overproduction, as well as fewer stockouts.

3. What are the major advantages to transforming manufacturing processes with Salesforce through automation?

- Salesforce allows manufacturers to automate their processes and eliminate mistakes, accelerate order processing and increase efficiency. It also releases resources to concentrate on other strategic activities which eventually results in cost saving as well as an increase in production turnover.

4. Is Salesforce useful in field service management in manufacturing?

- Yes, the Salesforce Field Service solution is used to optimize the organizational field operations by automating scheduling and routing, better tracking in real-time, and providing predictive maintenance. This will make sure that the dispatching of technicians is efficient, which will improve the quality of the services and minimize the downtime.

5. What should Salesforce do to enhance customer satisfaction in the manufacturing industry?

- Salesforce improves customer communication by giving real-time updates on the order statuses, automating the process of tracking the orders and making sure that the delivery time is correct. Those features enhance the customer experience by ensuring that their customer is always informed and they have more trust in the brand.

6. Does Salesforce scale in small and large manufacturing organizations?

- Yes, Salesforce is extremely scalable. Salesforce can be customized to the needs of your business, regardless of whether it is a tiny manufacturer or a massive enterprise. Its clouding system is easily customizable and expandable as your business expands.

7. What are the actions that manufacturers should undertake in order to have a successful Salesforce implementation?

- To be successful, manufacturers are to conduct a complete needs analysis, make sure that the departments cooperate, invest in training employees, and keep overseeing and changing the way the work processes. With such actions, the business would be able to make the most out of Salesforce and streamline its processes.

8. What is Salesforce contribution to the supply chain management in the manufacturing industry?

- Salesforce enhances supply chain management by giving real-time access to stock quantities, manufacturing plan, and purchase position. This will allow manufacturers to streamline their supply chain, minimize stockouts, and deliver on time, which will result in better customer satisfaction and operational efficiency.

9. Is Salesforce compatible with established manufacturing systems?

- Yes, Salesforce is able to integrate with the already existing systems like ERP, inventory management and production scheduling software. This connection also guarantees an overview of the business and enables manufacturers to use the existing systems and enjoy the strength of Salesforce in CRM and analytics.

10. What is the importance of AI in Salesforce in manufacturing?

- Salesforce Einstein, which is an AI-powered tool by Salesforce is very important in manufacturing since it offers predictive analytics. It assists the manufacturers in ensuring that they make correct predictions of demand, maximize their production schedules and minimize waste. AI helps to make better decisions as well by giving actionable information and automating redundant duties.

Also Read: What Are the Key Benefits of AI Agents in Manufacturing?