The Ultimate Significance of 3D Printing in Industry 4.0

Industry 4.0 is the fourth industrial revolution, where cyber-physical systems are integrated into the manufacturing process. 3d printing is playing a pivotal role in Industry 4.0, as it is acting as an accelerator across multiple industries.

3d printing eases the production of complex shapes and structures, which is why it is perfect for prototyping and manufacturing. Additionally, 3d printing is much faster than traditional manufacturing methods.

The automotive industry is one of the first industries to adopt 3d printing fully. Several automakers brands are already using 3d printed car parts. However, the role of 3D printing in industry 4.0 is only expected to grow in the coming years.

What Is 3D Printing?

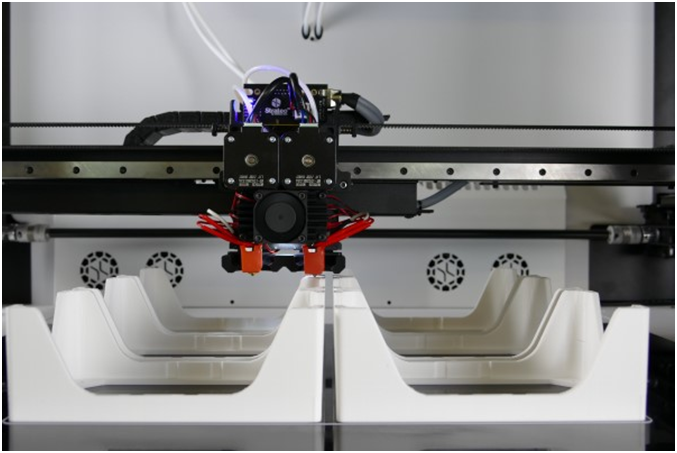

3D printing, also known as additive manufacturing, creates three-dimensional objects from a digital file. 3d printers use various materials, including plastic, metal, and glass, to create objects. In this process, the 3D printer deposits successive layers of material until the thing is complete.

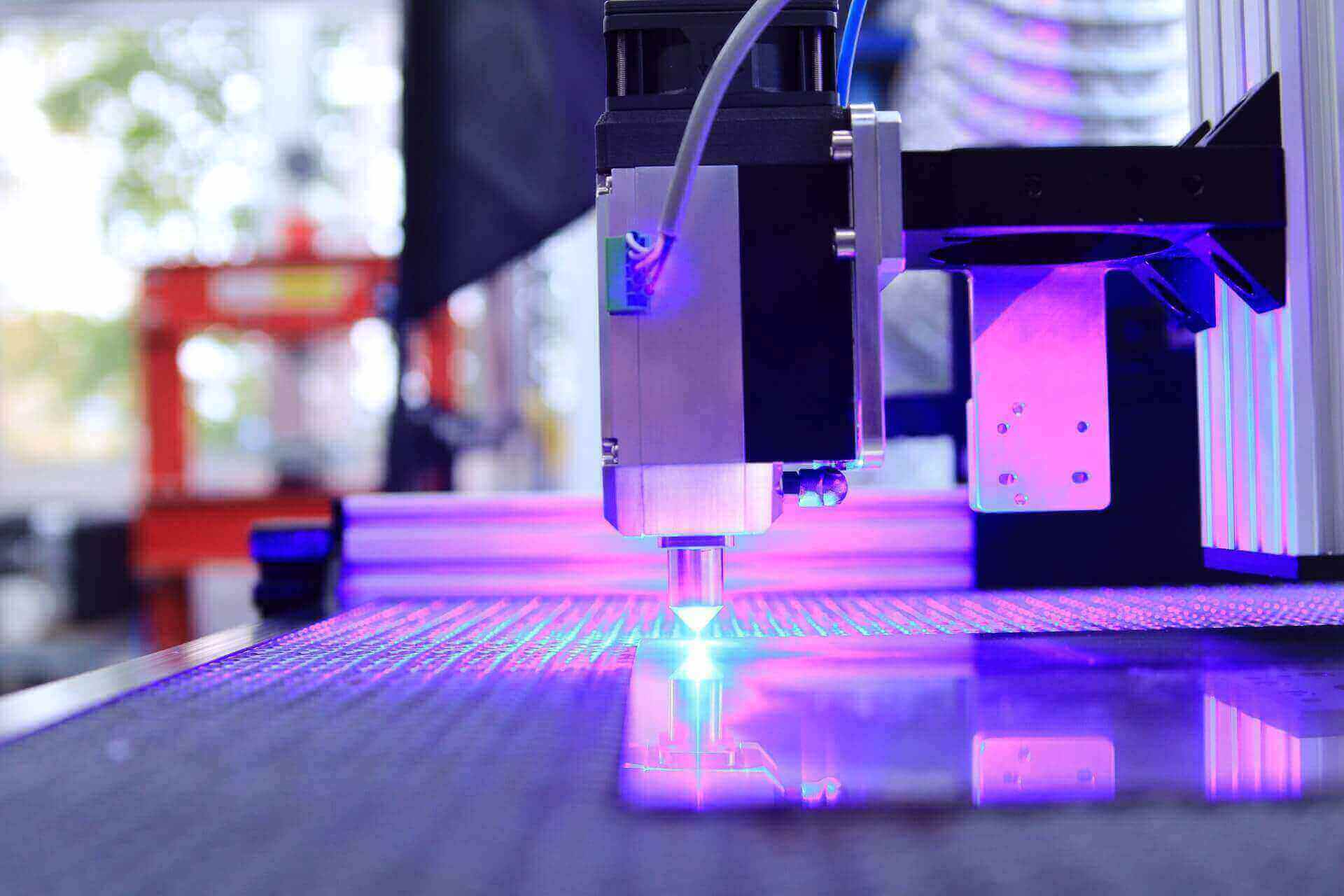

There is a variety of 3D technologies available to create objects. The most common technology is Fused Deposition Modelling (FDM), where the printer deposits melted plastic filament onto a build platform, layer by layer. FDM is ideal for rapid prototype building. Other technologies include Stereolithography (SLA), where a UV laser cures liquid resin into a solid object, and Selective Laser Sintering (SLS), where the powder is fused with a laser.

Also Read: 3 ways to be creative with promotional banners

Advantages Of 3D Printing inIndustry 4.0

Additive manufacturing is one of those few production technologies that come to a mature implementation quickly. There are several cutting-edge benefits of 3d printing technology, including:

Faster Prototype Development:

In the traditional manufacturing process, prototyping can take weeks or even months. However, with 3d printing solutions, the entire process can be completed in a matter of days. It is because machines can 3d print objects quickly and easily.

Every industry needs to develop faster prototypes to stay competitive. It is especially true for the automotive and aerospace industry, where new designs are constantly created. Thus, 3d printing aids companies to gain a competitive edge over their rivals.

Lower Costs:

Conventional manufacturing methods are expensive and time-consuming. On the other hand, 3D printing services are much more affordable and efficient. For instance, the automotive industry can save millions of dollars by using 3d printing for prototyping and small-scale production runs.

The affordability of 3d printing is also benefiting developing countries. Even small-scale OEMs can now afford to have their 3d printers and produce parts and products locally. This modernization helps to create jobs and stimulate the economy.

Greater Design Flexibility:

In traditional manufacturing, designers are limited to producing objects created with moulds. However, with 3d printing technology, there are no such limitations. 3d printers can create objects of any size and shape, which gives designers greater flexibility in their designs.

This increased design flexibility allows for the development of new products and technologies. For instance, several aeroplane manufacturing companies are designing lightweight parts to make their aeroplanes more efficient and cost-effective.

Improved Quality:

Unmatched quality is among the most significant advantages of 3d printing for industry 4.0 applications. The objects created with 3d printers have better dimensional accuracy and surface finish. Additionally, the risk of defects is also lower in 3d printed objects.

This improved quality is attributable to the use of advanced software and printers. Additionally, 3d printing allows for better quality control as every object can be individually checked for defects. With growing popularity, several companies have already started offering affordable 3d printing in Melbourne and several other places.

Industrial Applications Of 3d Printing:

3d printing is a paradigm shifter for Industry 4.0 implementation. This technology offers several cutting-edge applications across multiple industries. Some of the vital industrial applications of 3d printing are:

Automotive:

In the automotive industry, 3d printing is being used to develop prototypes and small-scale production runs. This technology is also being used to create engine parts and other complex car components.

Aerospace:

3d printing is playing an innovative role in the development of aerospace technologies. For example, this technology is used to create lightweight parts for airplanes and spacecraft. Additionally, 3d printing is also being used to produce fuel nozzles and other engine parts.

Medical:

3d printing technology has several applications in the medical field. For example, this technology is used to create implants, prosthetics, and artificial organs. Additionally, 3d printing is also being used in drug development and clinical trials.

Food And Beverage:

3D printing is also transforming the food and beverage industry. For example, this technology is used to create chocolate, pizza, and other food items. Additionally, 3d printing is also being used to create packaging for food and beverage products.

The Future Of 3D Printing:

3d printing is growing and finding its place across multiple domains rapidly. As a result, this technology is expected to become more affordable and accessible in the coming years. Additionally, 3d printers are also likely to become more versatile and capable of printing a more comprehensive range of materials.

With the rapid growth of 3d printing technology, it is expected that this technology will significantly impact different industries in the future. Along with large-scale manufacturers, small companies will also benefit from this technology. With growing demands, it has become easier for companies to start additive manufacturing. Anyone can quickly get 3d printing services in Perth or any other city and get started with this modern manufacturing.

Wrapping Up!

3D printing is the key accelerator playing a pivotal role in faster Industry 4.0 implementations. With growing popularity, anyone can search for 3d printing locations near me and quickly start professional manufacturing. This technology offers unmatched quality, design flexibility, and a wide range of applications. In the coming years, 3d printing is expected to become more affordable and accessible.